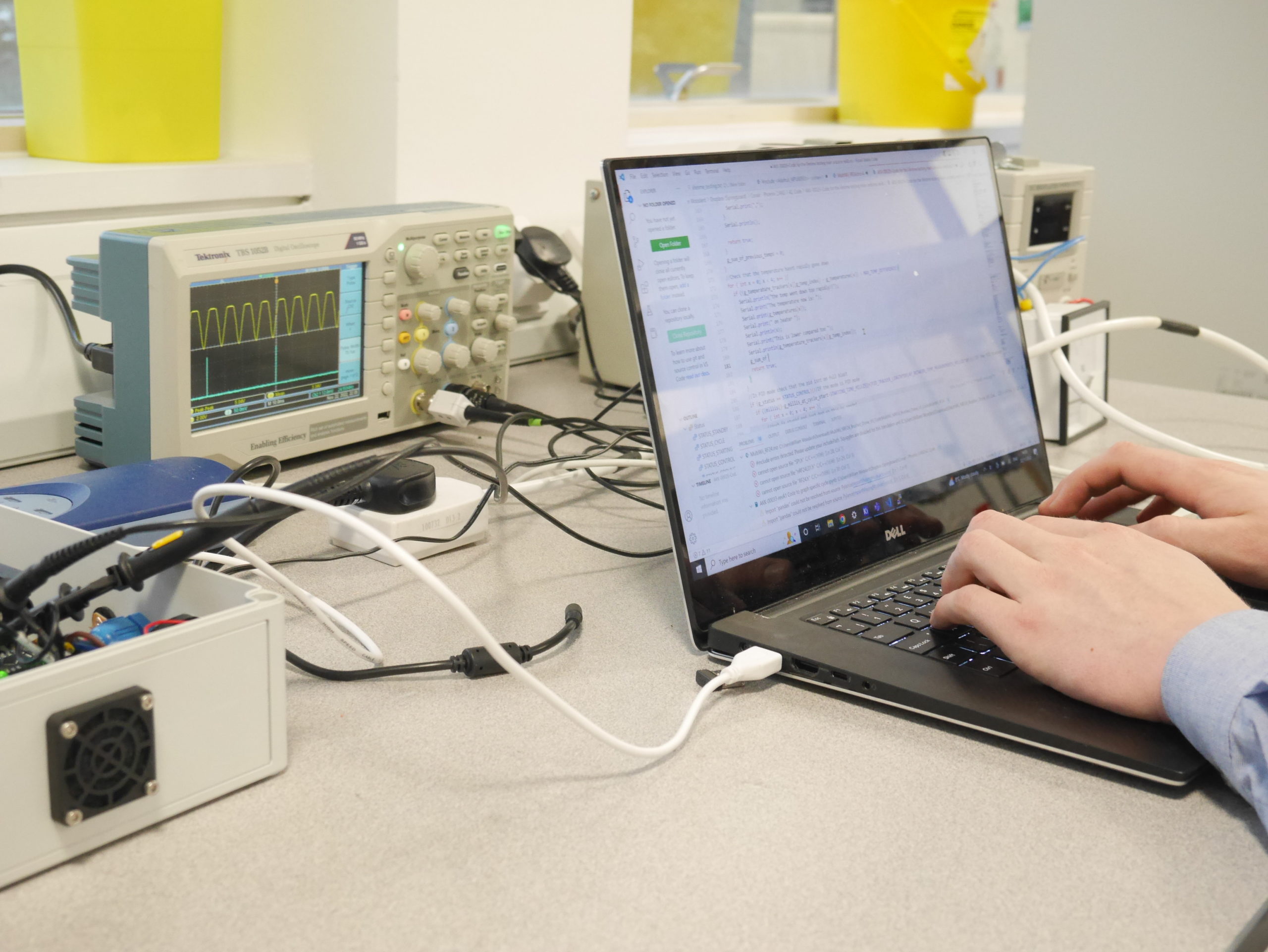

Forensic engineering is an art in itself and getting to the bottom of a complex problem is what we do best. From real-life application of functional maps, interaction matrices, cause effect chains, energy models, sensitivity analysis to ‘Top Down’ testing we can undertake numerous tests to ensure that your device is safe and functioning as it should.

Identifying design flaws and weaknesses

Forensic engineering allows for the systematic analysis of devices to identify any design flaws or weaknesses. By scrutinizing the components, materials, and manufacturing processes, our engineers can pinpoint areas of concern or risk that might lead to failures or malfunctions down the line. Thorough investigation at the start of the project allows for calculated testing and removes the guesswork.

Our extensive lab spaces host a variety of technical equipment allowing us to conduct extensive product testing and metrological investigations in-house. Additionally our in-house machining capabilities mean we can make bespoke rigs, fixtures and components for rapid prototyping and testing.

Find out how we helped a clientImproving product reliability

Through forensic engineering investigations, you can gain insights into how devices perform under real-world conditions. By analysing failed components or systems, we can uncover the root causes of failures and implement design improvements to enhance product reliability. Statistical analysis, Monte Carlo simulation, numerical modelling and finite element analysis can shed light on the underlying interactions leading to unexpected failure modes, using scientific theory to guide practical measurements and adjustments. This iterative and systematic process fosters continuous improvement, resulting in devices that are more robust and dependable.

Find out what type of analysis saves timeEnsuring Regulatory Compliance

In many industries, compliance with regulatory standards is non-negotiable. Forensic engineering helps companies to ensure that their devices meet all relevant regulations and standards. By conducting thorough investigations and adhering to industry best practices, they can demonstrate due diligence in product safety and quality, mitigating legal risks and regulatory penalties.

Read about the importance of design controlsFacilitating Continuous Improvement

Forensic engineering is not only about identifying failures but also about learning from them to prevent recurrence. It gives you valuable data that informs future design decisions and process improvements. This culture of continuous learning and refinement is essential for staying ahead in rapidly evolving industries.

Find out how a design review helped launch a product